Mercedes Opens the First OEM In-House Battery Recycling Plant

Nov 09, 2024

Mercedes Opens the First OEM In-House Battery Recycling Plant

Mercedes-Benz has opened a battery recycling facility in Kuppenheim, Germany with a capacity to produce enough recycled materials to build 50,000 new battery modules per year.

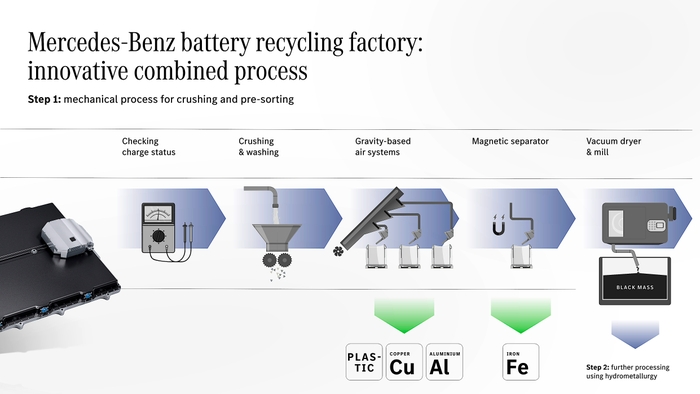

This is a plant that combines a hydrometallurgical recovery process along with the necessary mechanical breakdown of old batteries. That mechanical component separates the batteries’ plastics, copper, aluminum, and iron. The hydrometallurgical step is an 80℃ process that consumes much less energy and produces less waste than pyrometallurgical methods used elsewhere, according to the company.

MERCEDES-BENZ

The plant is net carbon neutral, operating on 100 percent green energy. It even has its own 350-kilowatt rooftop solar array. The facility is small, in relative terms, with an annual capacity of 2,500 tons. But Mercedes says that operating it will lead to higher production volumes over what the company describes as the medium-to-long term. The plant’s predicted recovery rate for valuable materials like cobalt, nickel, and lithium is 96 percent.

How Does It Work?

The first step in handling batteries is to check their state of charge, so they can be discharged if there any juice still left. Then the battery modules go onto a conveyor belt that carries them through a process where they are mechanically crushed and then washed and the materials are separated into coarse and fine bits. A gravity-based air system teams with magnetic separators, a grinder, and a series of sieves to break out the plastics, copper, iron, and aluminum, which are then packaged by type.

Related:Laser technology for EV battery recycling

MERCEDES-BENZ

The “black mass” contained in the dried coarse material also gets separated. This portion gets dumped in with the majority of the black mass that has already been strained out in the finely ground material, then the whole lot gets dissolved into a liquid leaching solution. Undissolved graphite gets filtered out and packaged, along with any precipitated iron and aluminum.

Finally, valuable materials like copper, cobalt, manganese, nickel, and lithium are each recovered, one after another through a multi-stage chemical separation process. The cobalt and nickel are then crystalized.

The Project

Mercedes has partnered with Primobius for the factory. That is a joint venture between the recycling plant, the mechanical engineering company SMS Group, and the process technology developer Neometals. Together, they are studying the process chain for recycling improvements, including in the areas of logistics and reintegration of the materials into the supply chain. “As a pioneer in automotive engineering, Europe's first integrated mechanical-hydrometallurgical battery recycling factory marks a key milestone towards enhancing raw-materials sustainability,” said Ola Källenius, Chairman of the Board of Management of Mercedes-Benz Group AG. “Together with our partners from industry and science, we are sending a strong signal of innovative strength for sustainable electric mobility and value creation in Germany and Europe.”

Related:EV Battery Recycling Requires More Efficient Processes

MERCEDES-BENZ

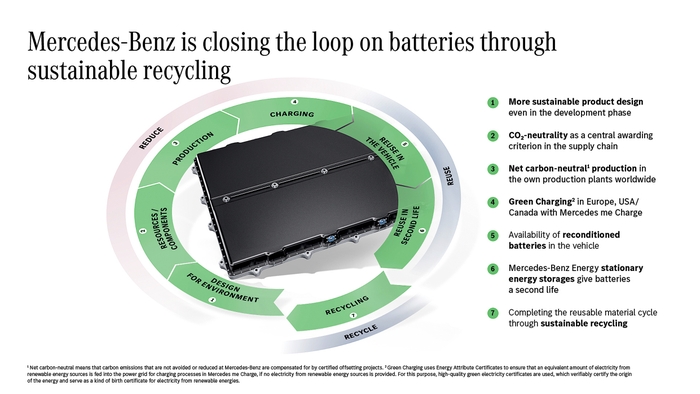

Mercedes’ “Design for Circularity” approach targets circular design, value retention, and closing the loop on raw materials. As part of this effort, Mercedes reconditions salvageable batteries for use as repair parts for its EVs. Lesser batteries get repurposed for stationary storage applications as backup power for the grid.

“We are systematically deepening our expertise in the battery value chain,” stated Jörg Burzer, Member of the Board of Management of Mercedes-Benz Group AG,

responsible for Production, Quality & Supply Chain Management. “The innovative technology enables us to recover valuable raw materials from the battery with the highest possible degree of purity. This turns today's batteries into tomorrow's sustainable mine for raw materials.”