Engineering Lessons from the James Webb Space Telescope

Oct 25, 2024

Engineering Lessons from the James Webb Space Telescope

Sitting in the audience for the Advanced Manufacturing Minneapolis keynote, “Sensors in Space: Learnings from Designing NASA’s James Webb Telescope,” I was in awe.

Dr. Jonathan Arenberg, chief mission architect for science & robotic missions at Northrop Grumman Space, wasn’t just describing a telescope’s construction and journey into space. He was describing a journey of “imagination” that required his engineering team to expand their horizons, in more ways than one.

The telescope is the largest and most powerful to launch into space, and the engineering team moved heaven and earth to get it there, so to speak. The telescope’s “mirror, when deployed, is six and a half meters,” Arenberg told the audience. “That's roughly seven and a third times the collecting area of Hubble. Webb weighs 55% as much at the level of the satellite. The Hubble at the satellite level is 11.1 metric tons. We're a little over six.

“Webb is first and foremost, a journey of imagination. We had to imagine this giant system and the consequences of dealing with a large, delicate, important system,” he added.

“What the scientists really wanted was a machine to see the beginning of the time,” he continued. “So, whenever we had a hard day at work when I was feeling a little down . . . I had to remind myself I had been given a job to design a machine to see the beginning of time, and I figured if that didn't get me out of bed, I needed to really reevaluate my life choices. I got out of bed every day. Sometimes I didn't go to bed, and I'm still excited about it.”

Related:Northrop Grumman Space and Siemens Digital Industries Software Keynotes Announced for Advanced Manufacturing Minneapolis

Here are some of the discoveries Arenberg’s team learned along their engineering journey.

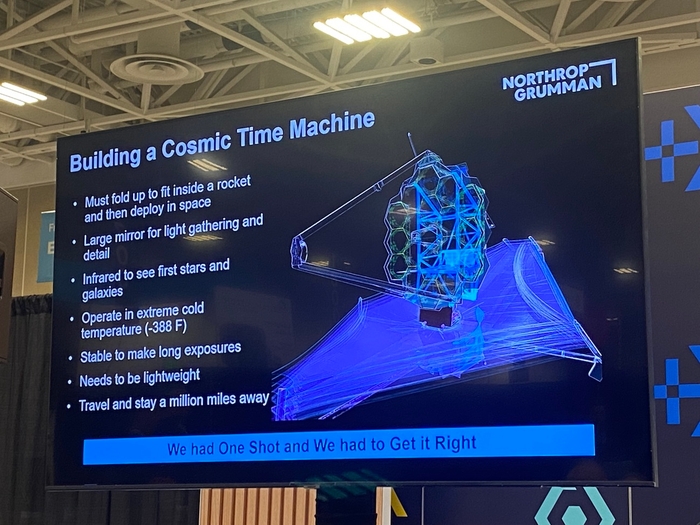

They needed the heart of a poet; the perseverance of an athlete, soldier, or fireman; and physics on their side

“This is a bit of a design challenge, right? We're imagining a telescope larger than the rocket it goes in, which means it's got to fold up. It's got to be light enough to get off the planet. If I took the Hubble design, and I scaled it up, it would weigh something like 75 metric tons, and it still wouldn't get off the planet, even with the new rockets coming online. So, we had to think differently. We had to think revolutionary, not evolutionary, and to have an engineering revolution, [you] need to have the heart of a poet that believes you can be successful, the perseverance of an athlete or a soldier or fireman and that kind of bravery. And you also have to have good physical skills, because we have to tell a story within the constraints of the laws of physics. So, you can't just say, ‘Oh, I'm just going to invent a telescope that's 15 times more massive.’ A little bit of proof is necessary.”

Related:NASA’s James Webb Telescope: Exacting Design and Constant Testing

The mission of the James Webb Space Telescope engineering team. DAPHNE ALLEN/INFORMA MARKETS ENGINEERING

They had to build their own solutions and test, test, test

Even though the telescope is considered “to be the mother of all sensor systems” and “the most engineered sensor system that we have produced of late,” Arenberg said, the team needed to develop new sensors “just to get the data to validate the models, to prove the poet's argument that, yes, we can build this system.”

This included developing several sensors to build and prove the telescope’s structural backbone and more. The team even developed sensors to manage accumulation on the telescope’s mirror once in space.

And that mirror needed to be very large in order to observe infrared light and “discern fine details because we are looking back to the beginning of the universe. We have to look between the stars in the foreground and the galaxies in the foreground, and we have to understand where the photons come from. So, we have to be able to separate them and not be confused,” he said.

“To do this mission, we needed a large telescope. That's what drove us to an unprecedentedly large mirror, and not one that was a little smaller, that was easier to implement. We did the hard thing because the science demanded it has to be in the infrared, because of the expansion of space, the light that comes off the early hydrogen burning monster stars in the visible and the ultraviolet, because space is expanding, comes to us in the infrared. That means we had to be large, we had to be stable, to be able to keep all the image quality high,” he continued. “This is the size of a house. We had to predict it was going to be stable at all kinds of frequencies for very long and slow so we could take long pictures, deep exposures, up to 10 days at a time, and not blur it, and high frequency, so the individual images are not jittered.”

Related:Behind the Development of the James Webb Space Telescope

They had to practice, practice, practice

“We had to think of how we practice, right? If there's any musicians in the hall, you know the old saw of, 'How do you get to Carnegie Hall? Practice, practice, practice.' I amended that to say, 'How do we get to L2, our operating point? Practice, practice, practice, calculate.' Practice some more. Do some more calculations, think,” he said.

For example, the engineering team built full-scale models to practice driving system hardware around using construction equipment. They had to practice activities such as folding the telescope’s sun shield to be able to fit into the cone of a rocket and then be able to unfold it in space.

“This is not like folding a tent. . . . We have to use a crane. We've got to use a lot of other things,” he said. “Again, practice, practice, practice. So, every technician who touched the sun shield, of which there were many, they all had to be checked out on the development model before they would be allowed to move to the cleanroom.”

They had to question anything unexpected

“We had a number of invented sensors, radiometers, in addition to thermal diodes and deep space sensors. We put that in the chamber just before the critical design review to prove that our design would work. And guess what? It worked better,” Arenberg said.

But this was “both wonderful and terrifying, because our models didn't explain why it was better, which meant we couldn't explain it; we would have to think that it could change and be worse. So, we dug in, looked at the data, did some more experiments, and in fact, found out that there was missing physics in our interpretation. When we included it, we could explain it to better than the uncertainty in the test, and we were allowed to go ahead," he said.

It turns out that the missing physics was “an assumption that emissivity and absorption were equivalent over all ranges, and because of the range of temperatures, that's not true,” he added.

They had to collaborate

Arenberg told the audience that “some 700 industrial concerns contributed, including 300 science organizations split into 17 countries, in 29 or 30 US states, three national space agencies spread over 12 time zones.

“So, this is not only an engineering feat—it's an organizational and contracting and export control feat,” he said.

Arenberg spoke about the James Webb Space Telescope—which will help scientists better see “solar systems ours and theirs”—October 17 at the Engineering Theater at Advanced Manufacturing Minneapolis. He has led major astronomical programs and development of optical, space, and laser systems over his 30-year career. For even more details on the engineering behind the James Webb Space Telescope, read our article after Arenberg’s DesignCon keynote earlier this year.