Virtual Prototyping Gains Momentum

Oct 01, 2024

Virtual Prototyping Gains Momentum

While physical prototypes will not soon disappear, they’re certainly becoming a less prevalent part of the design cycle. Reduced costs and the rapid speed-to-market are the driving advantages. As for disadvantages, they’re getting reduced as the simulation software improves.

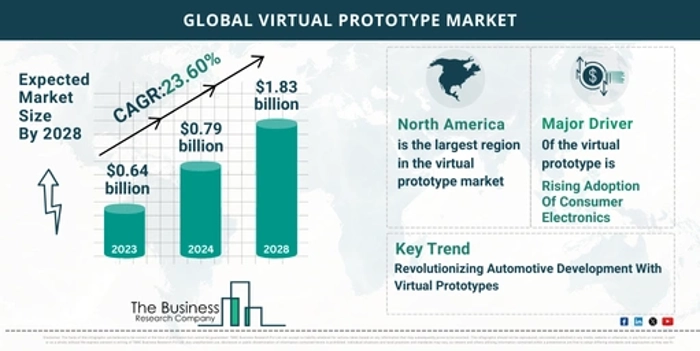

The Virtual Prototype Global Market Report 2024 by The Business Research Company (TBRC) revealed that the size of the virtual prototype market is expected to reach $1.83 billion In 2028 with an annual growth rate of 23.6%.

TBRC attributes the growth to increasing demand for product simulation, rising costs of physical prototypes, the need for faster time-to-market, environmental concerns, and regulatory pressures. Other factors include the rise in remote work culture, demand for digital twins, emphasis on sustainability, increased focus on cybersecurity, and the proliferation of smart manufacturing.

Improved software is also factor. We’re seeing the integration of virtual reality and augmented reality into prototyping, the integration of predictive analytics, the emergence of collaborative virtual platforms, and the adoption of blockchain for secure data sharing.

Image courtesy of The Business Research Company.

Siemens’ Simcenter Testlab is geared to reduce reliance on physical prototypes

In its latest update to its Simcenter Testlab, Siemens Digital Industries Software is offering to help advanced manufacturers on their journey to zero prototypes. The update is also designed to help users develop products faster, smarter, and earlier.

Related:Could Simulation Advance Your Testing Programs?

Simens noted that the journey to zero prototypes really means zero full product prototypes, with physical testing still playing a critical role in developing the components that make up the full system. Tests of these components are then used to correlate and update the corresponding simulation models to ensure they accurately predict the real world. This ultimately helps development teams test different variations and configurations faster than they could before and is enabled by new capabilities in Simcenter Testlab to enhance testing efficiency, expand testing capabilities, improve collaboration and automation.

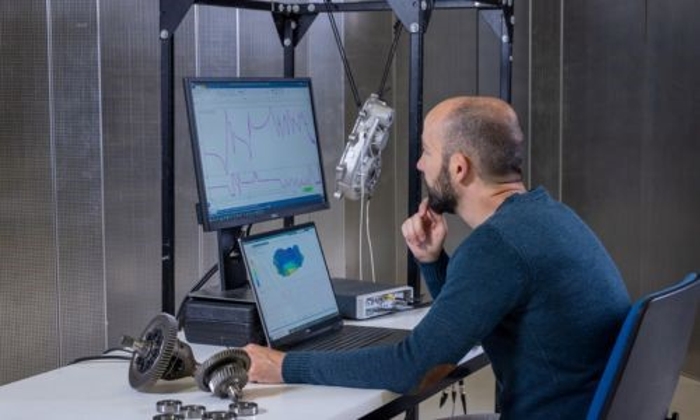

Modal Analysis of a gearbox housing with Simcenter Testlab and Simcenter SCADAS Mobile. Engineer looking at screen during physical testing. Below the screen Simcenter 3D is open and combined. Image courtesy pf Siemens.

Simens developed the update to help users reduced the need for physical prototypes. “Manufacturers are looking for opportunities to accelerate their zero prototypes initiatives," said Wilfried Claes, product manager director of Simulation and Test at Siemens Digital Industries Software. "Advances made with Simcenter Testlab demonstrate how the use of virtual pre-test planning with the reuse of digital twin data, when combined with centralized data management collaboration capabilities and flexible, rugged data acquisition hardware designed for use in the field, are changing the testing industry."

Related:Simulation Key to Future Engineering

Siemens spelled out the features in the Simcenter Testlab update

Impact testing efficiency

Up to a 50% overall efficiency gain in complex impact testing campaigns can be gained with the latest updates. First, test engineers can reduce time by reusing existing CAD data to define instrumentation and points for impact. The additional support for using multiple hammers in parallel during impact testing allows engineers to extend the frequency range, which is necessary for evaluating the unique characteristics of electric vehicles.

The testing software automatically merges the data from multiple hammers on the fly so you can see results during testing. Since engineers no longer need to change hammer every time and manually merge data, Simcenter Testlab reduces overall testing time and allows testing teams to cover more impact points in less time.

Simcenter SCADAS RS hardware for acquiring road loads during a field test on a motorbike. Image courtesy of Siemens.

Expanding Testing Capabilities

This update to Simcenter Testlab also introduces three key new capabilities to expand the testing capabilities of the software/hardware offering. The new Virtual Prototype Assembly tools bring together physical test and simulation data to create virtual prototypes with a focus on enabling performance evaluation of different configurations and variants before building physical prototypes.

Related:4 Ways Virtual Prototyping Fuels Cooperation in Automotive Design

Alongside this, the new NVH (Noise, Vibration and Harshness) Simulator allows users to listen to a product prototype before it is built, supporting time domain loads and auralizing combined testing and simulation results – which enables the development of pleasing experience for customers and evaluation against sound quality metrics. Finally, the new Mission Synthesis tools can streamline the durability testing process by defining mission profiles, acquiring real-life vibration data and synthesizing test profiles to predict potential failure points accurately.

Enabling Collaboration

The latest update to Simcenter Testlab also includes additional capabilities across data management and automation to help customers bring greater organization and centralization to key test data and to provide efficiency gains. The new Simcenter Testlab Data Management capability provides centralized storage for all NVH data, allowing easy retrieval and annotation across different contexts and collaboration between engineering teams by supporting storing single values, such as critical KPIs, and immediate replay of test data directly from the server without the need to download locally. In addition, the new Simcenter Testlab workflow automation tools can be used to automatically retrieve, process and publish data - reducing manual effort, minimizing errors and enabling consistent analysis and centralized data management.

Smarter Field Testing

For test professionals conducting test processes in the field, the Simcenter SCADAS RS hardware combined with Simcenter Testlab software has been designed to enhance in-field data acquisition. Remote connectivity helps engineers validate the data being captured in real-time without having to be at the proving ground. New event marking capabilities let test technicians and drivers note when certain events occur during the test drive, helping the engineer understand and interpret test data more accurately. Finally, the hardware’s rugged design ensures in-field testing even in the toughest test conditions, from extreme temperatures to moisture, dust and high shock and vibration.